Where does your power come from?

North Dakota lignite coal

You flip the switch, and the light comes on. It’s as simple as that, right? Not quite. It takes a great deal of effort from a lot of people to keep your power flowing. It comes from numerous sources and flows over a complex grid of connections. It’s generated, transported, and maintained by people across the country whose work all has one final destination: your home.

The energy mix of the world today looks a lot different than it did several decades ago. Research and technological advancements have introduced a growing use of more diverse resources. However, as alternative energy has continued to become a more effective option, one resource has been a mainstay: coal. According to the U.S. Energy Information

Administration, coal was the second-largest energy source in the United States. In 2019, 23% of the energy generated in the U.S. was from coal.

Though the future of energy is uncertain, the most realistic way to plan for a reliable and robust energy future is to find the right balance of all of our resources. The numbers fluctuate slightly over time, but Cass County Electric Cooperative (CCEC) utilizes an energy portfolio consisting of 55% coal. At this point, it is still the most efficient and reliable energy source available in North Dakota. But just how does something pulled from the ground allow you to watch TV, charge your cellphone, and heat your home? It’s actually a very complex and time-consuming process.

Much of the coal used to make electricity for CCEC members comes from the Center Mine near Center, N.D. The mine is owned and operated by BNI Coal, which mines roughly 4.5 million tons of coal from the area each year. The mining process begins with exploration drilling, where BNI engineers gather information about the location of coal seams beneath the ground.

After a new coal seam is selected for mining and the appropriate leases and permits have been acquired, topsoil and subsoil removal can begin. These top layers of soil contain nutrients essential for local vegetation growth, so the soil is reserved for the reclamation process.

The earth below topsoil and subsoil is known as overburden. On some occasions, excavators and dump trucks are used to begin removing overburden, but the bulk of this work is done by some of BNI’s oversized equipment. Draglines with buckets larger than school buses are capable of removing overburden 120 feet thick. Though these tremendous machines do not harvest any coal themselves, they do much of the work to expose the seams.

Once the coal is exposed, collection can begin. In the process known as coal ripping, BNI uses bulldozers equipped with specialized claw-like ripper shanks that break coal into smaller pieces. It can then be picked up by front-end loaders and placed into BNI’s fleet of bottom-dump haul trucks. The majority of the coal is then taken to the Milton R. Young power stations adjacent to the mine, where it is consumed to produce electricity.

Lignite coal, the type found in North Dakota, has a higher moisture content than other coal types, making it much costlier to transport. For this reason, lignite coal mines and power plants are often very close together to make coaltransportation more efficient.

A coal-fired power plant produces electricity like many other plants—coal is burned to heat water and generate steam, which is used to propel a turbine within a generator. The electricity then travels along transmission lines from the plant to its end-consumers.

Land reclamation efforts involve reshaping the land into its original contour. Topsoil and subsoil are replaced and seeded with grasses, hay, or small grain crops. Reclaimed land is required to be at least as productive as it was before being mined, and BNI is responsible for the land’s performance for a minimum of 10 years after reclamation.

Extensive effort has been made to reduce power plant emissions. Over the last decade, Minnkota Power Cooperative, CCEC’s power supplier and owner/operator of Milton R. Young Station, has invested millions of dollars into emission reduction technology, and the investment has been paying off. Based on data measuring pounds emitted per kilowatt-hour of electricity used by CCEC members, emission of sulfur dioxide has dropped by over 90%, emission of nitrogen oxides and solid particulates has dropped by over 70%, and emission of carbon dioxide has dropped by over 30%.

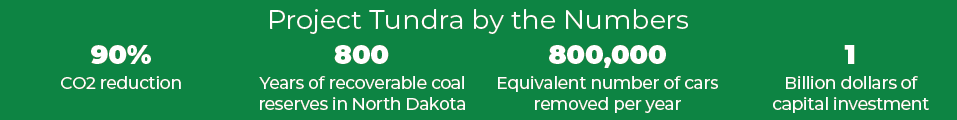

Minnkota and Cass County Electric strive to provide affordable and reliable electricity. It’s in our DNA. The need for electricity continues to grow. To support the rising demand for electricity and meet the needs of environmental mandates, Minnkota is looking into nextgeneration technology with Project Tundra. Project Tundra is an initiative to retrofit the

Young Station with technologies to capture 90% carbon dioxide (CO2) emissions produced by either generator. Those emissions would be stored safely in a secure geologic formation more than a mile underground. If the project moves forward, North Dakota would be a world leader in developing next-generation energy technologies. For more information on Project Tundra, visit https://www.projecttundrand.com/.

CCEC’s diverse energy mix is carefully balanced to ensure affordable, reliable power for members while continuing to progress with renewable energy, emission reduction technology, and efficient energy use. We look out for our members, working dutifully to keep the lights on and serve as stewards to our environment.